STAHL+TECHNIK

STAHL + TECHNIK

STAHL + TECHNIK is the German-language trade journal for steel production, processing, application technology, innovation and management.

The target groups are steel production companies, steel processing companies (from hot and cold rolling to surface finishing), steel processing companies (forming, joining, sheet metal processing), the supply industry, universities, technical colleges and associations.

Frequency of publication: 6 issues 2024

6th year of publication

Print run: 5,000 copies

Key topics

Content:

Plant engineering; Metallurgy; Innovation; Coke-making technology; Technology; Companys; Markets; Forming technology; Materials and production, Digitization; Steel application; Precious metals

Categories:

Steel trade; Management; Events; Profession and career; Energy and Environment; Technology, strategy and management trends; Profiles of the industry players; Comments; Interviews; Well-founded technical reports; Scientific background information

Dates and planned topics

ALL Ad closing dates | Publication dates

2024

Issue 1 - February 2024 - Plant engineering | Automation | Digitalisation | AI

Ad closing date: 16 January | Printing material: 18 January | 06 February

Steel Production

World's first 3-strand continuous slab caster starts production

In September 2023, Chinese steel manufacturer Tangshan Donghua Iron and Steel commissioned the world's first 3-strand slab caster. The new 3-strand solution offers several advantages: With three strands, the plant achieves a significantly higher production capacity than conventional 2-strand casting plants. Two conventional 2-strand systems with a similar capacity would have required around twice as much space and correspondingly higher investment costs. In comparison, the operating and maintenance costs are also lower.

At thyssenkrupp Steel, an innovative process based on automated, camera-assisted surface inspection for the early detection and processing of surface serial defects in flat steel products has been successfully developed and introduced into production. The method can be used to successfully detect and process serial defects in preliminary units that are difficult to identify. The method developed enables the quality manager responsible to initiate early and proactive corrective measures to reduce or avoid quality costs.

With the commissioning of a new cold strip line, thyssenkrupp Steel is able to produce harder and thinner flat steel products that are used in cars and electric motors. It is the world's first double reversing mill with Hyper UCM silicon steel technology, which offers a significantly higher production output than a single-stand cold rolling mill.

Plant engineering

With the P2.e generation, SEW-EURODRIVE is expanding its product portfolio in the field of industrial planetary gear units. Compactness, flexibility and a high thermal limit power make the gear unit the ideal solution for continuously operated heavy-duty applications with limited installation space.

Digitalisation

The exchange of data between suppliers and customers is a challenging task. Data is currently used for process development (e.g. for refractory materials) as well as for the development of quality predictions. Thinking further, the data can be used to calculate the CO2 footprint, for example.

The thermal management of torpedo ladle cars plays an important role in the transport of hot metal from the blast furnace to the steelworks. This paper presents the development of an AI system to support decision-making in the selection of the most energy-efficient torpedo car. The application uses a simulation-based digital twin consisting of reduced-order models of validated FEM models to predict the temperatures of the refractory lining and hot metal in the torpedo ladles.

Steel Trading, Distribution and Processing

With the introduction of the CliMore® brand, the BENTELER Steel/Tube Division will in future summarise its CO2-reduced steels and steel tube products under a uniform and catchy product brand. Three label levels - Advantage, Ambition and Excellence - characterise how the steels or tubes were produced and which types of energy were used. The first CliMore® hydraulic line pipes were delivered to a German manufacturer of agricultural and construction machinery in November 2023.

Steel traders often offer additional services - such as processing - as part of steel service centres. This raises the question of when an original steel trader becomes a manufacturing company. On the one hand, processing can be carried out "in-house", for which the steel trader maintains and invests in its own machinery. Or the steel trader can go down the outsourcing route and look for service providers to take over the processing for him. Both methods have advantages and disadvantages. HEINE+BEISSWENGER uses the example of saws to illustrate the entrepreneurial approach.

AICHELIN Service has coordinated and implemented the relocation of two AICHELIN chamber furnace lines for Winning BLW GmbH, a leading company in the field of precision solid forming. These were moved from different locations to Winning's new plant in Penzberg (Bavaria). One of the two lines has already been successfully in operation since July 2023, while the second is due to be commissioned by the end of 2023.

LogiMat, Stuttgart/Germany - 19.-21.03.2024

Issue 2 - April 2024 - Special AISTech | Electric steel | Refractory | Special tubes

Dates:

Ad closing date: 13 March | Printing material: 15 March | Publication date: 01 March

Special: Trade fair preview wire and Tube 2024

wire 2024 and Tube 2024 - the world's leading trade fairs for the wire and cable industries and the tube sector

wire and Tube will once again offer a complete overview of the wire and cable industry and the tube scene worldwide from 15 to 19 April 2024 in Düsseldorf. wire 2024 presents machines and systems for the manufacture and processing of wire and wire products such as fasteners and springs, tools and aids for production technology, materials, glass fibre technologies, special wires and cables as well as innovations in sensor, control and testing technology. Tube 2024 presents the entire process chain of the tube industry - concentrated and compact: machines and systems for the production, finishing and processing of tubes as well as raw materials, tube products and accessories are part of the extensive range on offer. This range is supplemented by the areas of tube and large-diameter pipe, OCTG technology and profiles.

Interview: Technology trends for the production of long steel products

Dr Thomas Maßmann, Executive Vice President Long Products at SMS group, answers questions about the presentation at wire & Tube and current market developments. The Hybar project in the USA (rebar production with green energy in a continuous process) will be explained. He also talks about the benefits and importance of the service business for SMS group.

New standards in hydrogen tube technology

The Steel/Tube Division of metal process specialist BENTELER has expanded its HYRESIST product range. The HYRESIST line pipes are specially designed for transporting hydrogen, as the energy carrier of the future places high demands on the material properties of the steel pipe. Users from industry, the mobility and energy sectors now have more options when it comes to finding the right line pipe for their individual hydrogen projects.

Steel production / plant engineering

Schmiedewerke Gröditz renews electric arc furnace with KSK technology

KSK and Schmiedewerke Gröditz announce the completion of a milestone. The 50 t electric arc furnace has been modernised. The new water-cooled furnace roof in tubular design, including dust chamber and recooling circuit, was successfully put into operation at Schmiedewerke Gröditz. The furnace characteristics, the KSK components and their properties are described.

Precise in-line thickness and width measurement in the manufacture of flat products

Mecorad had further developed the capabilities of the "wtl series" radar measurement solutions. The wtl series provides precise and robust information from the most difficult process stages in continuous casting and hot rolling of flat, long or heavy plates. The software on which the solution is based distributes digital information to each production stage for flexible production and beyond.

Cleaning exhaust air systems with sound pressure

Exhaust air systems in steelworks are exposed to high dust loads at high temperatures, which leads to dust deposits in individual components. Known consequences of this contamination are increased pressure losses, greatly reduced heat transfer, imbalances on fans, clogged filters, etc., which leads to reduced productivity and even damage. Cleaning is therefore carried out at defined intervals. If the system has to be shut down for this, production downtimes usually have to be accepted. In order to keep the production plant permanently clean, permanently installed sonic horns can be used to remove dirt from the system during the ongoing process by means of sonic pressure.

PLANT ENGINEERING

Powerful industrial planetary gearboxes

With the P2.e generation, SEW-EURODRIVE is expanding its product portfolio in the field of industrial planetary gear units. Compactness, flexibility and a high thermal limit power make the gear unit the ideal solution for continuously operated heavy-duty applications with limited installation space.

DIGITALISATION

Optimisation of data exchange in steel mill processes

The article describes the importance of digitalisation in the context of the steel manufacturer's collaboration with refractory suppliers. It discusses the importance of data exchange and describes data collection during production. Optimisation potential is explained, such as the creation of a data collection plan. This supports the discussion among experts and is still superior to AI as a tool. Finally, cooperation with customers is explained.

A needle in a haystack in seconds

Over 1,600 tonnes of metal, rolled into coils, pass through the BILSTEIN Group's production facilities every day. To eliminate the risk of mix-ups, the global player relies on the ibaDatawyzer-ICC coil identification software from iba AG. For coil identification, ibaDatawyzer-ICC primarily uses the longitudinal thickness profile of the rolled coil.

AI-supported software in order management

GLA-WEL GmbH, an owner-managed, medium-sized metalworking company based in Melle, Lower Saxony, relies on AI-supported software for its order management. The solution enables the metal contract manufacturer to successfully automate customer orders and enquiries and increase efficiency. Incoming orders from customers vary greatly and include up to 100 different items. It used to take several hours to enter such an order manually. The newly introduced AI-based software, on the other hand, now manages this in just three minutes on average thanks to intelligent automation.

Steel trading and distribution

Continuity and tradition: Andernach & Bleck GmbH & Co. KG celebrates over 120 years of successful bright steel history

The history of Andernach & Bleck is described and the current range of services in the bright steel sector is presented. This includes special profiles whose product development is carried out in close co-operation with customers. The future direction of the company will be outlined.

Trade Fairs| Exhibitions| Events

wire & Tube, Düsseldorf/Germany - 15.-19.04.2024

HANNOVER Messe, Hanover/Germany - 22.-26.04.2024

Freiberger FeuerfestSymposium, Freiberg/Germany - 22.-24.04.2024

Control, Stuttgart/Germany - 23.-26.04.2024

IESSS, Aachen/Germany - 24.-25.04.2024

AISTech, Columbus/USA - 06.-09.05.2024

13th EEC, Essen/Germany - 03.-06.06.2024

Issue 3 - June 2024 - Plant engineering | Belt processing | Refractory | Steel statistics | Special Cranes

Dates:

Ad closing date: 04 May| Printing material: 08 May| Publication date: 01 June

Special: Cranes

Trade Fairs| Exhibitions| Events

Surface Technology, Stuttgart/Germany - 04.-06.06.2024

Sensor + Test, Nuremberg/Germany - 11.-13.06.2024

Nordic Steel Konferenz, Luela/Sweden - 26.-28.06.2024

Issue 4 - July 2024 - Special sheet metal | Digitalisation | AI

Dates:

Ad closing date: 11 June| Printing material: 13 June | Publication date: 02 July

Topics: will follow

Trade Fairs| Exhibitions| Events

Issue 5 - September 2024 - Special sheet metal | Continuous casting

Ad closing date: 20 August| Printing material: 22 August | Publication date: 10 September

Topics: will follow

Trade Fairs| Exhibitions| Events

AMB, Stuttgart/Germany - 10.-14.09.2024

ICR – International Colloquium on Refractories, Aachen/Germany - 18.-19.09.2024

11th European Continuous Casting Conference, Düsseldorf/Germany - 07.-10.10.2024

EuroBLECH, Hanover/Germany - 22.-25.10.2024

Issue 6 - November 2024 - Decarbonisation | Green Steel

Ad closing date: 15 October| Printing material: 17 October | Publication date: 05 November

Topics: will follow

Trade Fairs| Exhibitions| Events

HÜTTENTAG, Essen/Germany - 19.11.2024

More Media Information

Ad rates and sizes

Sofort Inserieren Order Advertisement

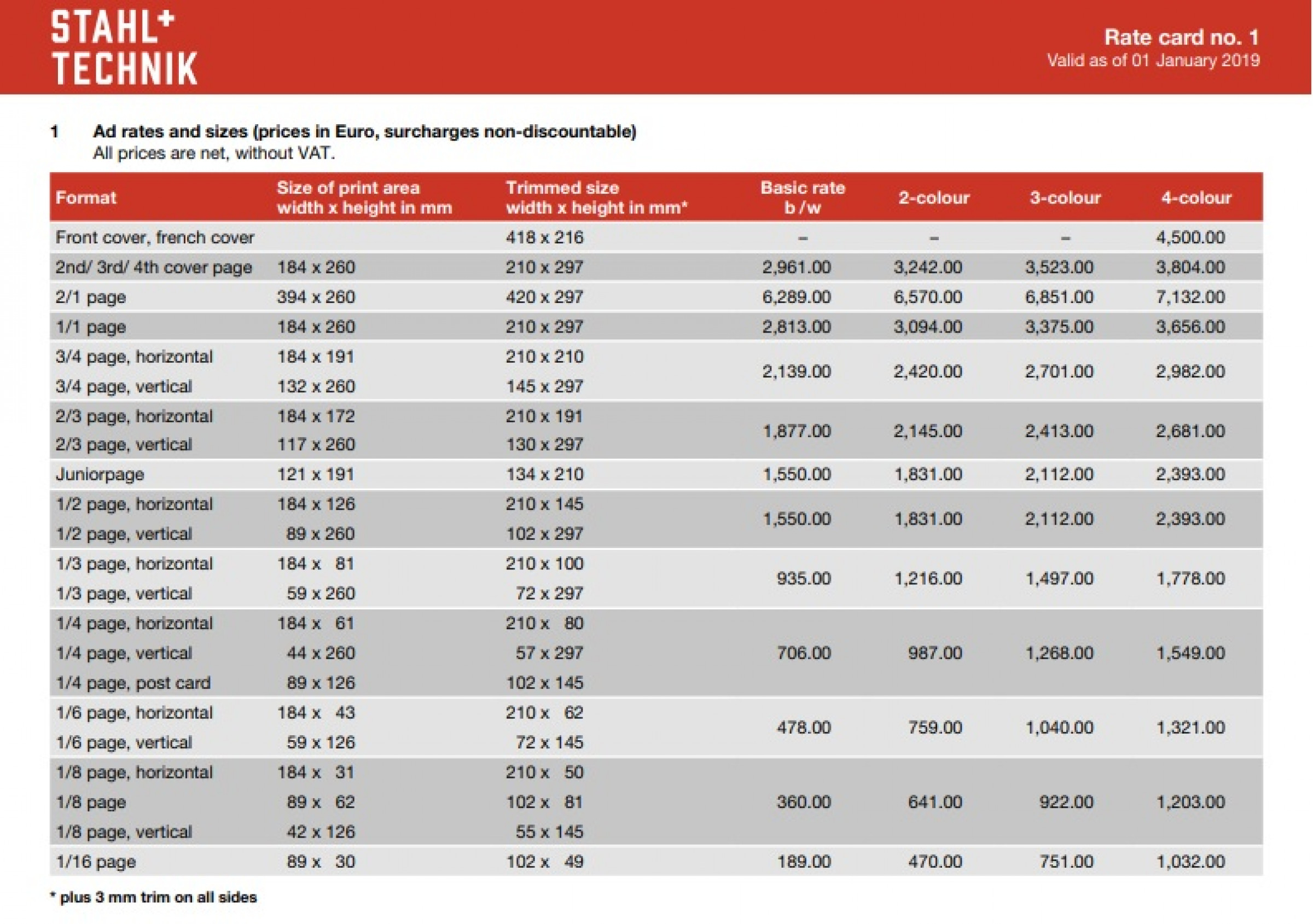

1) Ad rates and sizes

All prices are net, without VAT. Prices are in euro, surcharges non-discountable.

|

2) Surcharges: |

|

| Placement: 20 % surcharge for 1st right side, opposite Start and end of text on the b/w basic price (not discountable), 10 % surcharge for other binding placements with thecorresponding b/w-format price (not discountable). |

Color: Each standard color: 281,00 € 4c-color: 843,00 € Colour surcharges are not discountable Surcharge for special colours per color: 686.00 € Metal and fluorescent colors: on request |

|

Format: |

|

| 3) Discounts: For a booking period of one year |

|

|

|

Mengenstaffel 2 pages 5 % 3 – 5 pages 10 % 6 – 9 pages 15 % 10 – 12 pages 20 % from 13 pages 25 % |

|

Vacancies and job applications |

|

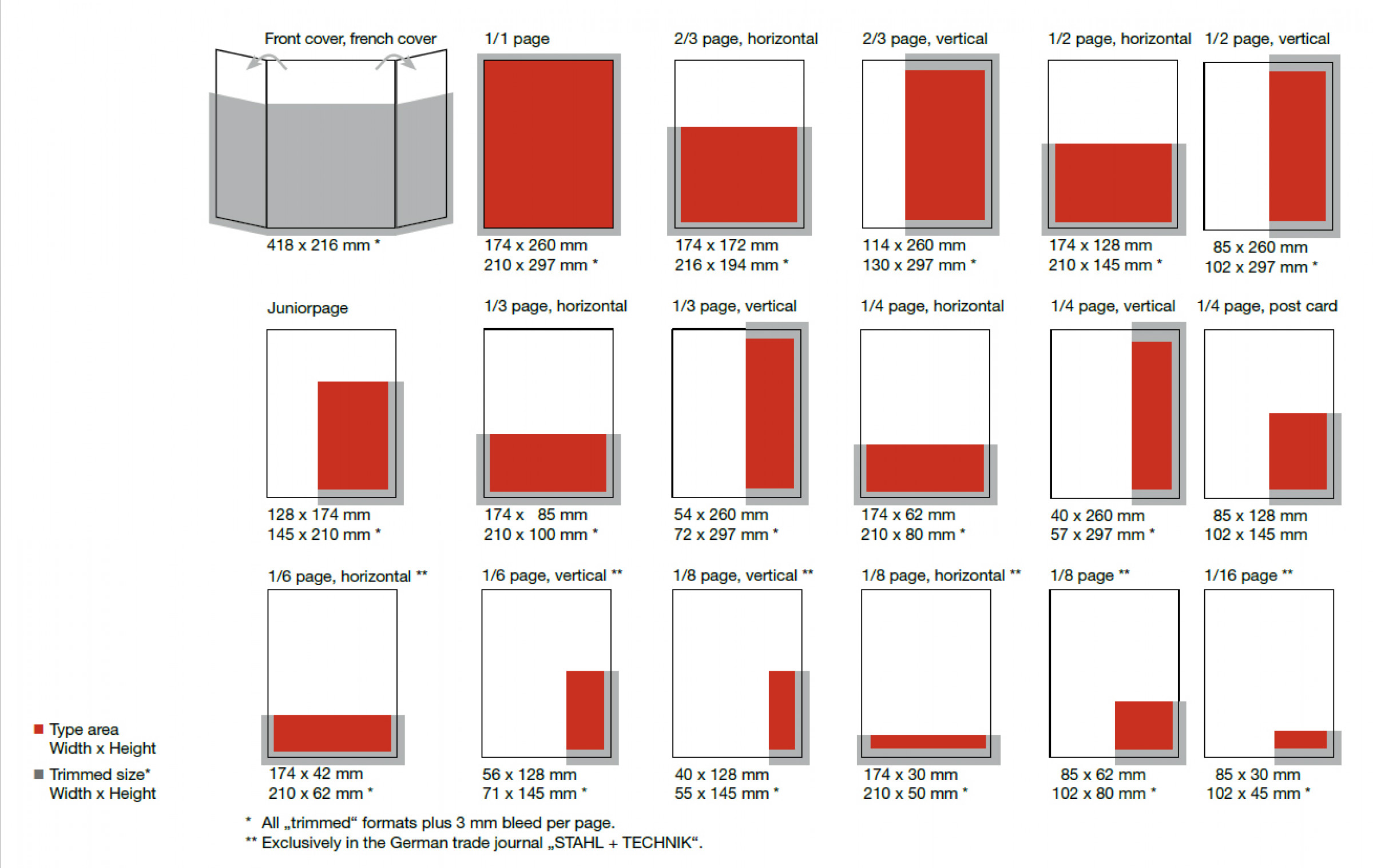

Formats and technical details

Ad rates and sizes

All prices are net, without VAT. Prices are in euro, surcharges non-discountable.

|

1) Size of journal: |

Print area: |

|

|

|

|

|

4) Colours: European scale (CMYK) according to ISO 12647-2 (PSO), spot colours on request. For conversion and control of the colour space (ICC Color Management), please refer to the standard ECI offset profiles. (The profil “ISO Coated v2” (ECI) in the package “ECI_Offset_2009” is available free of charge at www.eci.org). |

|

|

6) Archiving of data: As the data are archived, it is generally possible to use the data in an unchanged version for reprints. However, we do not assume any responsibility for the provided data. |

|

|

8) Contact: Katrin Küchler P: +49 211 1591-146 E-Mail: katrin.kuechler@dvs-media.info |

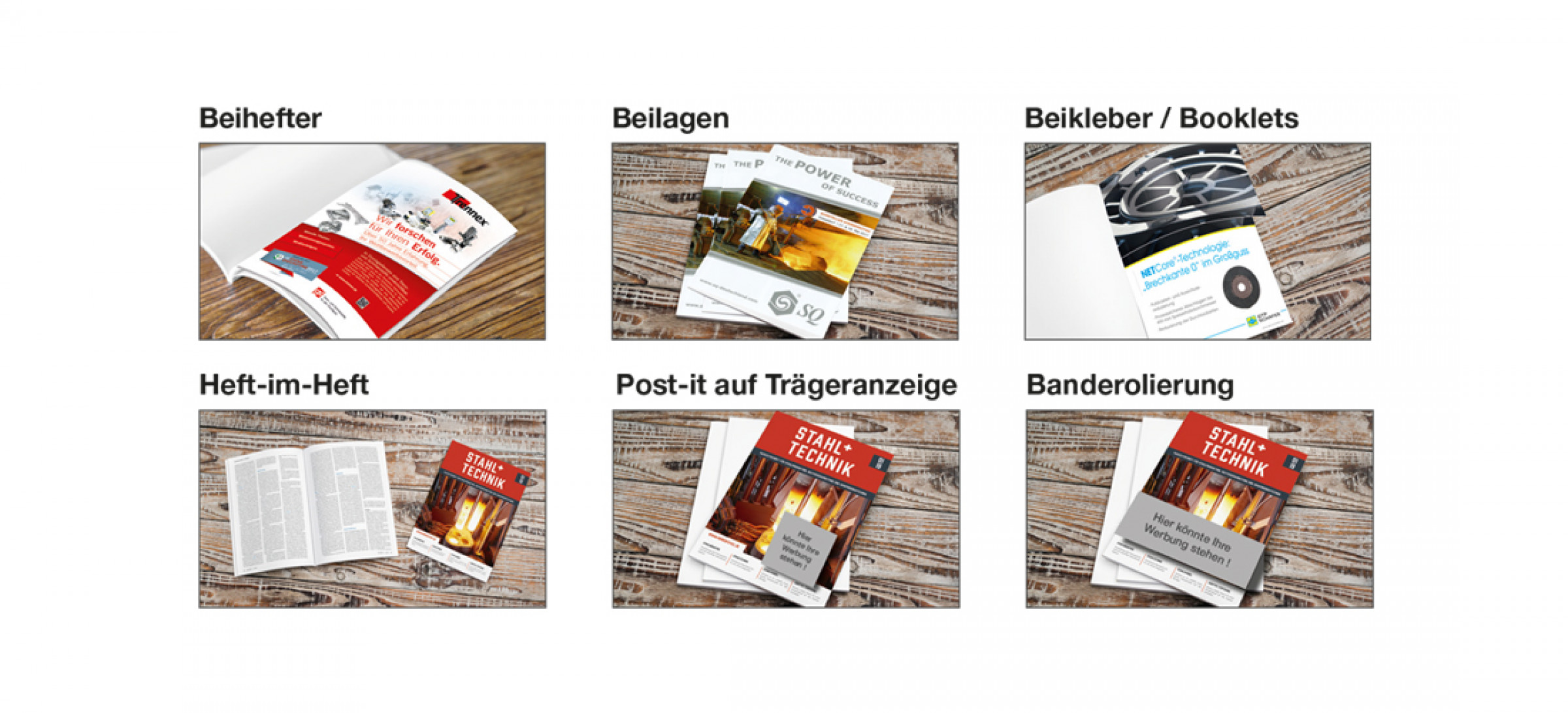

Special forms of advertisements

Bound-in inserts:

Discountable, 1 bound-in insert = 1/1 page ad

Weight up to 11g/sheet. Only whole circulation.

Minimum size untrimmed (also folded) 216 x 307 mm. Allowance for trim:

On top and at the bottom of the page 5 mm each, outside and inside 3 mm each for binding.

1 sheet = 2 pages 3,454 €

2 sheet = 4 pages 6,448 €

Loose inserts:

Weight up to 25 g

Not bound in, max. size 205 x 295 mm.

in domestic circulation: 3,255 €

in the total circulation incl. abroad: on request

3 samples requested from the publisher

Glued-on items:

On request

Advertorial:

The ideal complement to your classic advertising with an editorial-like background. You provide us with text/picture material and we layout it according to the magazine design:

2/1 pages, 4c: (10,000 characters incl. spaces) 7,489 €

1/1 page, 4c: (5,000 characters incl. spaces) 3,839 €

1/2 page wide, 4c: (2,000 characters incl. spaces) 2,513 €

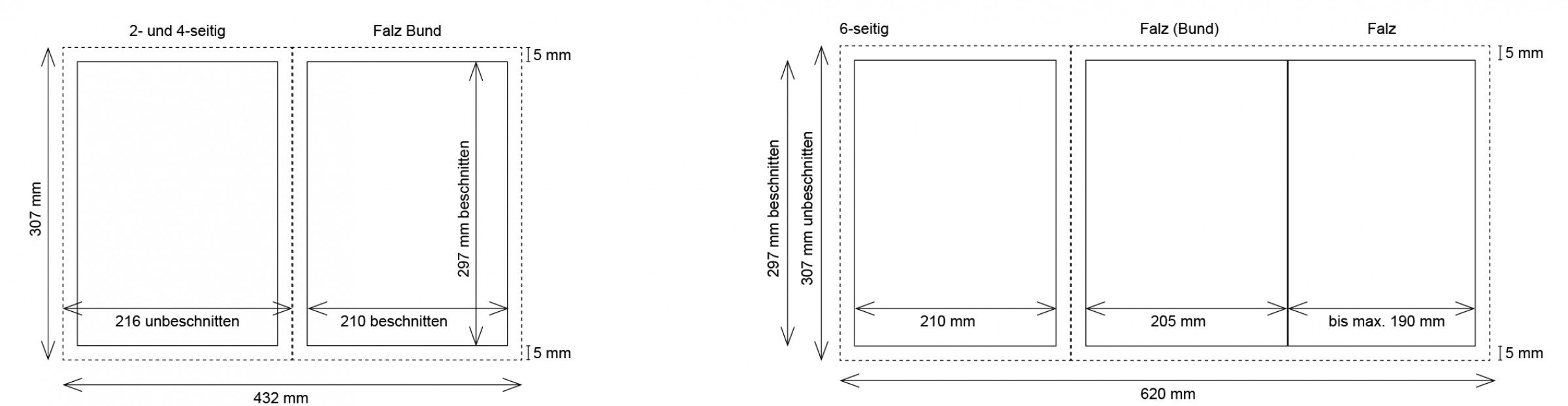

Technical details Bound-in inserts:

|

Bound-in inserts:: |

Technical details: |

|

Formats: Quantity: |

Shipping adress: |

Conditions and technical details inserts:

| Inserts: Conditions for order acceptance and confirmation by the publishing house are the presentation of a binding sample, if necessary a dummy sample with size and weight indication. Inserts may only be used for the sales program of an advertiser. The insert must be designed in such a way that the reader does not associate it with the text part of the magazine. The placement will be carried out according to the technical possibilities. Exclusively for MPT International. |

Technical details: As the material is inserted loose, i.e. without fixture of any kind, it must be a single piece. The inserted material must be delivered in such a condition that no additional handling or processing is required. Any extra work (e.g. folding) will be separately charged. Inserts printed on a material other than paper will not be accepted unless a compulsory sample has been furnished before, for checking its suitability for processing and shipping. Inserts consisting of several sheets must close up towards the binding, i.e. towards the inserting direction. |

Reference to insert: Reference to the insert will be included in the advertisers’ index free of charge. |

Deadline for delivery: Up to 10 days after the ad-closing date (see dates and planned topics on pages 2, 3 and 11) |

Quantity: On request |

Format: Max 205 mm x 295 mm |

Shipping adress: Prepaid delivery to: W. Kohlhammer Druckerei GmbH + Co. KG Augsburger Straße 722 70329 Stuttgart Indicate as reference: For „STAHL + TECHNIK“ or „STEEL + TECHNOLOGY“, Issue No. |

Clickable advertisements in E-Paper

Ads in the e-paper are only possible in combination with print ads.

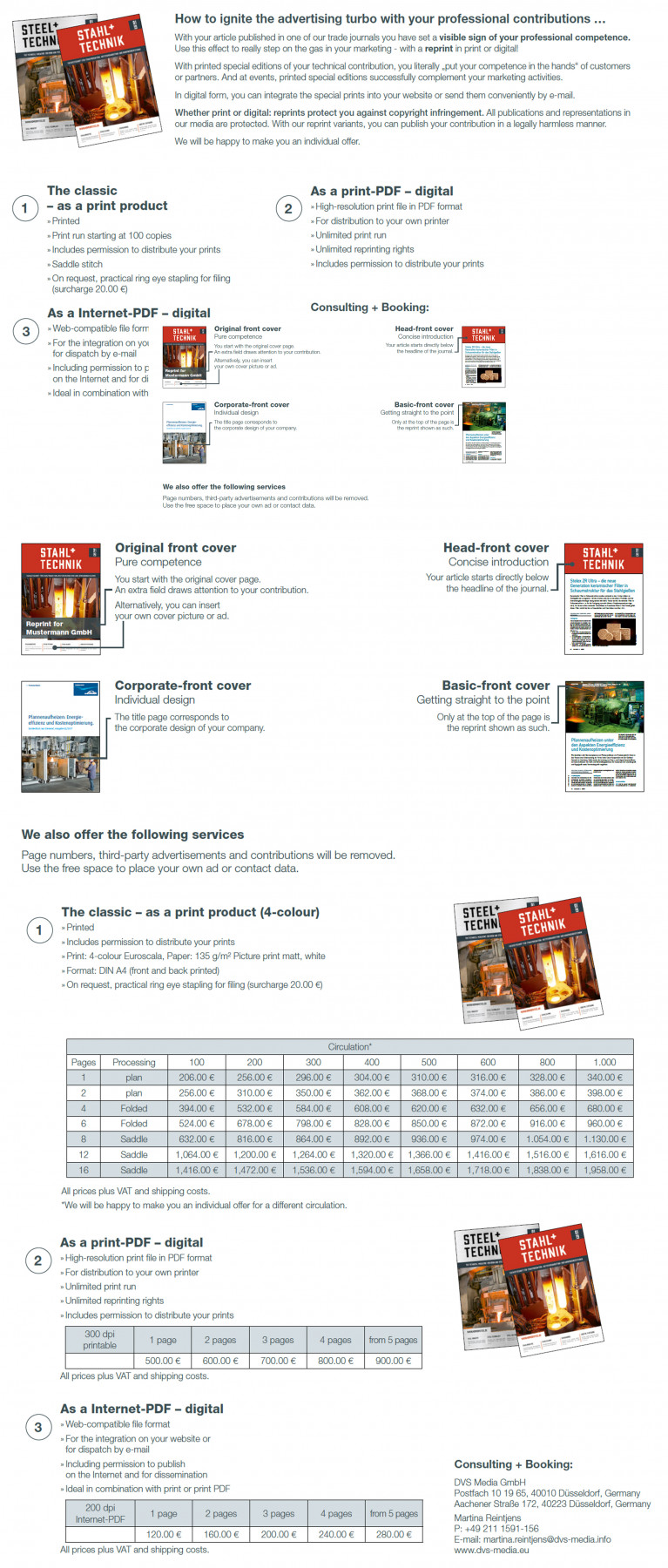

Reprints

Contact Person:

Martina Reintjens

T: +49 211 1591-156

E-Mail: martina.reintjens@dvs-media.info

Information sheet - Digital printing documents

The following conditions must be observed in order to accept digital advertisements/print documents and process them without any problems:

Terms of payment:

2 % discount on payments within 14 days and net price for payments within 30 days

from the date of the invoice.

Bank account:

Commerzbank AG, Düsseldorf

IBAN: DE91 3008 0000 0212 6151 00

SWIFT-Code: DRESDEFF

Deutsche Bank AG, Düsseldorf

IBAN: DE04 3007 0010 0155 7008 00

SWIFT-Code: DEUTDEDD

Contact

Ad sales

Editorial staff | Manuscript submission

Sales and Marketing

Susett Bendel

P: +49 211 1591-167

E-Mail: susett.bendel@dvs-media.info